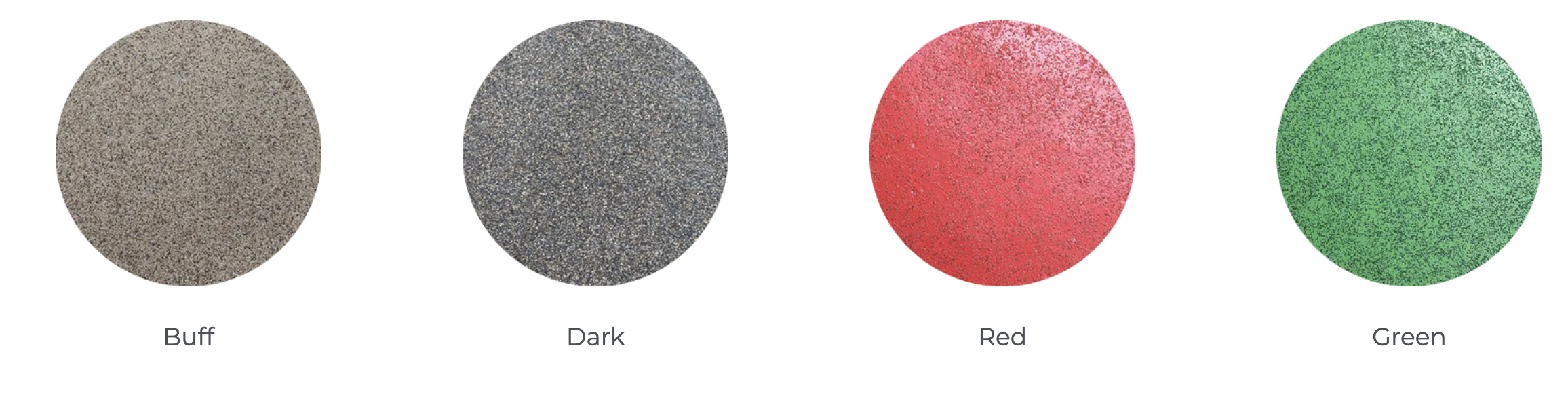

Anti-Skid Sheets enhance surface safety and durability. Available in Buff, Red, Green, and Dark, they can be purchased on the Red Stag Materials website. These 600mm x 1000mm sheets provide excellent skid resistance and are suitable for various substrates, including bitumen, concrete, and block paving.

1. Preparing for Installation

Before applying the anti-skid sheets, ensure the surface is clean, dry, and free from loose materials, dust, grease, or foreign matter. Proper preparation is essential for optimal adhesion and long-lasting results.

2. Application on Bituminous Substrates

- Clean and Dry: Thoroughly clean the surface and remove moisture using a gas burner.

- Optional Primer: Apply a suitable tack coat primer such as SWARCO PREFORMED Primer Spray 200 or SWARCO PRIMER Roll 100 if required.

- Lay the Sheet: Position the Anti-Skid Sheet on the pre-heated area with the aggregate side facing up.

- Heat the Sheet: Use a heat gun or gas torch with wide heat dispersion, keeping it approximately 30cm above the material. Move continuously to avoid scorching.

- Check for Fusion: The material should fuse evenly with no visible joins, and the edges should taper into the substrate.

- Cool and Inspect: Allow 5–10 minutes for cooling before inspecting the adhesion.

3. Application on Concrete and Other Substrates

-

Clean and Dry: Ensure the surface is completely clean and dry. Do not force-dry concrete.

-

Mandatory Primer: Apply SWARCO PREFORMED Primer Spray 200 or SWARCO PRIMER Roll 100 evenly across the surface.

- Allow Primer to Dry: Wait until the primer is fully dry before proceeding. Do not force dry the concrete surface.

- Follow Bituminous Application Steps: Continue from step 3 in the bituminous application guide.

Note: New concrete surfaces should cure for at least 28 days before application.

4. Application on Block Paving / Granite Setts

Block paving and granite setts present unique challenges due to potential surface movement and low porosity. Follow these guidelines:

- Use Primer: Apply SWARCO PREFORMED Primer Spray 200 or SWARCO PRIMER Roll 100.

- Assess the Surface: Ensure minimal movement between blocks and sufficient primer absorption.

- Apply Anti-Skid Sheets: Follow the heating and cooling steps from the bituminous application process.

5. Final Inspection and Troubleshooting

- Adhesion Check: Test adhesion by attempting to lift the sheet edges with a screwdriver.

- Bond Failure: If the sheet lifts cleanly without substrate residue, reapply heat.

- Substrate Issue: If substrate residue is visible, investigate the substrate integrity before proceeding.

6. Packaging and Storage

- Packing: Supplied in cardboard boxes, typically containing 5 sheets per box.

- Shelf Life: 12 months when stored in a cool, dry place away from direct sunlight.

- Storage Advice: Avoid exposure to moisture and extreme cold to prevent brittleness.

7. Product Links

By following these step-by-step instructions, you'll ensure a professional and durable application of anti-skid surfacing, enhancing safety and surface performance for years to come.