The Ultimate Guide to Stihl, Husqvarna, Milwaukee, Makita and Hilti Disc Cutters

Disc Cutters, also known as cut-off saws, power cutters or just Stihl Saws, are essential tools for construction, highways, civils and landscaping professionals. Whether its cutting through reinforced concrete or slicing asphalt or masonry, these machines are designed to handle some tough cutting conditions. However, selecting the correct saw and blade combination is crucial for achieving optimal performance.

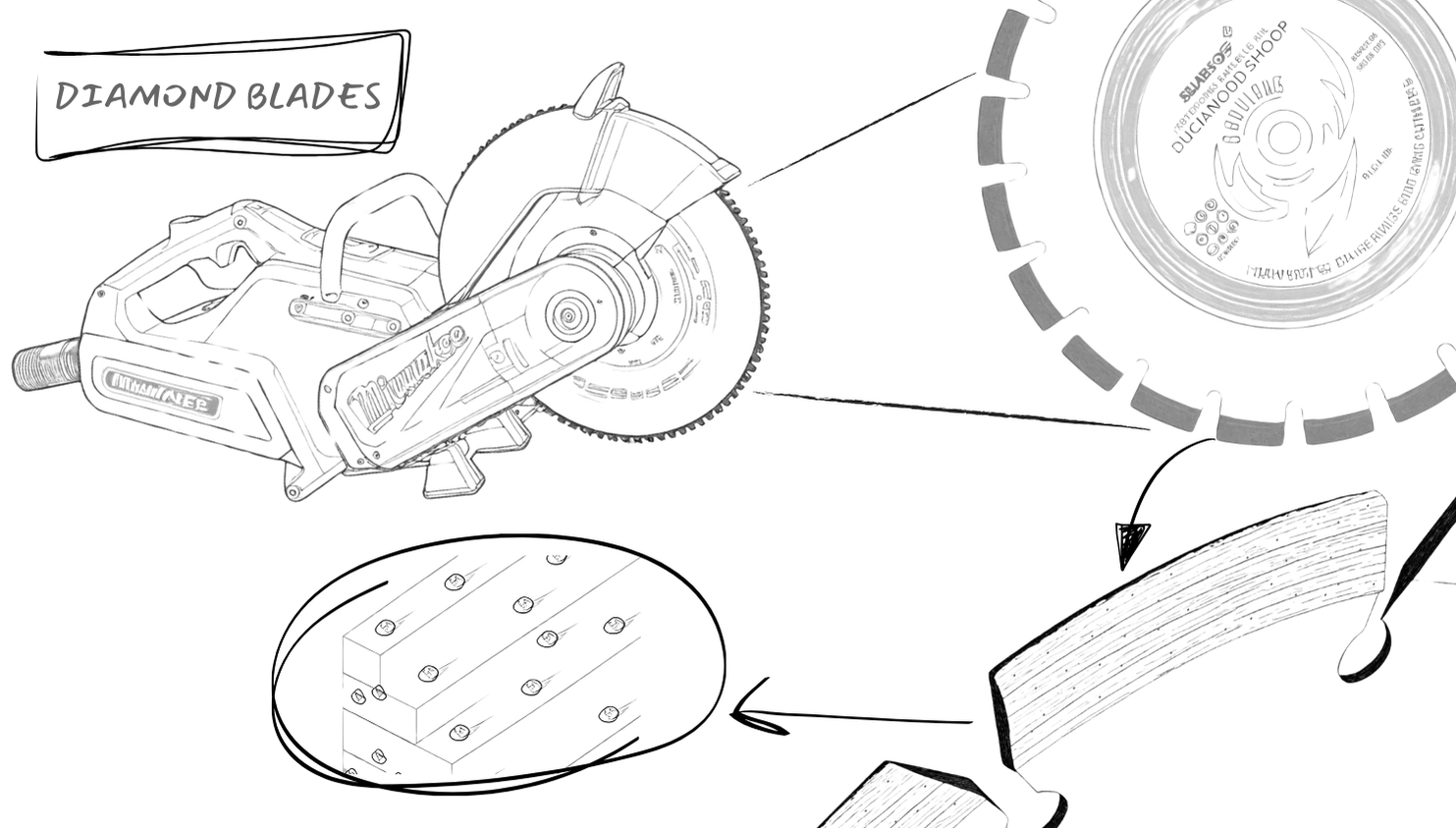

At Red Stag Materials, we offer a range of premium saws from trusted professional brands such as Stihl, Husqvarna, and Milwaukee, along with our own precision quality diamond blades to complement these tools. This blog provides a comprehensive comparison of the leading brands to help you make an informed decision for your next project. With the recent introduction of 12"/300mm battery powered saws, there is more choice than ever for the professional user. In this guide, we will explore the technical specifications, key features and cost considerations for each.

| Saw and Disc Combination It's an important place to start to clarify that with the wrong blade on any saw, the performance will be significantly impaired. The cutting experience will be slow, tiresome on the operator and leave a poor quality cut. The Diamond cutting market can be extremely complicated, you have to determine the best type of cutting wheel, whilst trying to unpick the difference between a £10 and £100 disc. |

|

Equipment Manufacturers

Traditionally, the disc cutter market has been dominated by two main players, Stihl and Husqvarna. In recent years however other players have entered the market with highly credible product offerings. Here we will assess each of the manufacturers and their experience.

Andreas Stihl founded in 1926 in Waiblingen, Germany, the company invented the first portable chainsaw which had a huge impact on the forestry industry across the globe. In 1964, Stihl introduced the TS 08, a petrol powered cutter which became the contractors essential tool. During the 1970s, the Stihl TS 50 was brought to market which offered improved features on the TS08. In 1993 the Stihl TS 350, a 56cc two-stroke disc cutter was launched which allowed the cutting of materials up to a depth of 115mm. A couple of years later the TS 400 came to the market with further enhancements on the existing saws. Since then the TS 410 and TS 420 was launched in the late 2000's which remain the models most commonly purchased to this day, with regular product developments being made. In 2024, Stihl released the TSA 300, their first 12" battery operated saw.

Stihl operate a restricted distribution model so only approved dealers and sub-dealers can distribute their products.

Husqvarna was founded in 1689 in Huskvarna, Sweden as a rifle manufacturer then moving into making sewing machines, motorcycles and bicycles. In 1959, the company ventured into manufacturing outdoor garden equipment with the release of it's award winning chainsaw. In 1960, the company released the Husqvarna 70 Disc Cutter, their very first petrol powered disc cutter. In 1965 the company launched a second generation version with the Husqvarna 180 power cutter, designed to handle more demanding tasks.10 years later, in 1975, the Husqvarna 225 was launched with further technological advancements. Fast forward to the mid 1990s and the K series of saws hit the market with the K 760 saw followed shortly afterwards by the K 970, a saw which would become one of the most desired on the market for many years. 2018 saw the release of the K 770 saw which included some improvements on the K 970 saw but the same key fundamental features. More recently, the Husqvarna K1 PACE was released which continues to the Husqvarna 12" battery saw solution.

Milwaukee Electric Tool Corporation, best known as Milwaukee was founded in 1924 in Milwaukee, Wisconsin, USA. The company developed the first 1/4 inch power drill, which became the standard for future power tool development. In the 1930's and 40's, the company developed a wide range of tools for the construction industry and US Military. In recent years, Milwaukee has become a leader in battery technology with a range of platforms for high performance. The company entered the disc cutter market in 2019 with the launch on the mini sub-compact multi-material cut-off tool. Later in 2019, the company launched the MX Fuel 350mm Cut-Off Saw which is a battery operated tool with a cutting depth of 125mm.

Milwaukee operate a restricted distribution model so only pre-approved resellers can distribute their products.

Makita, the highly popular power tool brand was formed in Japan in 1915 as an electric motor sales company. In 1958 the company built its first power tool, an electric planer. By 1978, Makita had launched it's first cordless power tool. This development in cordless technology set Makita up for being one of the market leaders in battery technology. At the turn of the millennium, the LXT lithium-ion battery platform brought even more power through cordless battery.

Hilti was founded in 1941 in Lichtenstein, initially manufacturing tools for the construction industry, however by 1955 they introduced a direct fastening tool which became the catalyst for global expansion and a wide portfolio of power tools including cutting equipment. In 2015, Hilti introduced the DCH 300 electric cutter which allowed cuts up to 120mm with a 300mm blade. In 2020, the DSH 600-X was launched, a petrol powered cut off saw.

Hilti only sell their products directly.

In addition the these manufacturers, other brands have attempted to introduce a disc cutter to the market which include Hitachi with their CM75EAP, the Hyundai HYDC5830 and Altrad Belle with their DC300E. These tools are not included within the comparison as they are not considered to be professional quality.

When it comes to selecting the correct manufacturer and model, there are a number of key areas to consider;

- Power Source

- Weight

- Portability

- Depth of Cut

- Noise and Emissions

- Vibration Levels

- Blade Speed

- Maintenance

- Running Cost

⚙️ Power Source

This wasn't a buyers choice in the past as most saws were powered by an internal combustion engine which would be fuelled by either 4-stroke or 2-stroke fuel.

2-Stroke Fuel is a mixture of petrol and 2-stroke oil, typically at a ratio of 50:1 (50 parts petrol to 1 part oil). This type of fuel is used as it allows for a simpler engine design, allowing the saw to be lighter. The easiest way to mix 2-stroke oil is using a 'One Shot' bottle which contains 100ml of oil which can be poured directly into a 5 litre fuel can for the perfect mix. Stihl HP Two-Stroke Oil 100ml is just one of the options available

4-Stroke Fuel is straight petrol, using either E5 or E10 petrol. The number relates to the Ethanol content of the fuel, E5 = 5% Ethanol 95% Petrol. E10 burns slightly cleaner than E5 so has environmental advantages however fuel economy of E5 is slightly better. 4-Stroke Fuel is typically used on equipment where portability and weight is not of the highest importance so is rarely used in Disc Cutters.

Development in battery technology has now brought the ability for a battery tool to be capable of delivering enough power to the saw for high performance cutting. Advancements in the technology utilising large capacity lithium-ion batteries with higher energy density has made it possible for a single battery to provide runtime suitable for a professional to switch from petrol to battery.

The ongoing global drive to reduce carbon emissions and in the cases of construction sites, remove the need for hydrocarbon fuels, battery technology allows this sustainable development. Alongside the removal of the need for petrol, battery offers zero emissions, reduced noise and often require less maintenance.

⚙️ Weight

The weight of the saw can often be the first thing a user will assess when buying a saw but a light saw isn't always the best saw for performance.

A lighter weight saw is easy to handle, especially when working on awkward tasks such as vertical cutting or overhead work. The lighter saw also reduces the risk of operator injury and limits fatigue during longer working periods. However, a heavier saw can provide greater stability which can in turn provide a better quality and more precise cut.

Alongside the overall weight of the saw, the distribution of weight is another key guide to the suitability of a saw, a poorly balanced saw, where the weight is overly distributed to either the front or the back of the saw, will yield a poor user experience regardless of the overall weight. This is especially relevant with battery saws where the weight of the saw without a battery can be extremely light whereas when the battery is added, the weight increases.

⚙️ Portability

The ability to move the saw around, from site to site, would typically be focused largely on the weight of the saw. Whilst this is a key factor, the durability of the machine is equally just as important, cut off saws are often used in rugged, tough environments, outside and in robustly transported in the back of a van or pickup. To withstand this, the saw needs to have the characteristics which will withstand the tough nature of the construction industry.

⚙️ Depth of Cut

A common misconception with saws is that a 12" saw will cut 12" in depth however this is not the case. The actual cutting depth is dependent on the saw and the cutting disc used.

Typically, a 12" / 300mm saw with a 300mm diamond blade will cut a depth of around 100mm - 110mm and a 14" / 350mm saw with a 350mm diamond blade will cut a depth of around 125mm.

In some cases, a 14" saw can accept a 12" blade, which allows for a smaller lower cost cutting disc to be used when depth of cut is not critical.

⚙️ Noise & Emissions

The amount of noise and emissions generated from a saw are often important factors for certain users due to the level of noise created by a saw and the emissions created by the traditional petrol engine.

Noise generated by a saw can exceed 100db (A) which will require hearing protection, The use of a battery powered saw will have a significant positive impact on the level of noise created.

Fuel powered saws will emit exhaust gases containing carbon monoxide, which have both environmental and health implications. The battery powered saws will eradicate any emissions, which can be a significant benefit when the saw is to be used in an indoor environment.

It is estimated that replacing a regularly used saw which consumes 200 litres of fuel annually with a battery saw could yield an annual carbon saving of 306kg co2e.

⚙️ Vibration Levels

Vibration is a key factor when choosing your disc cutter, as long term use of a saw with exposure to high levels of vibration can lead to fatigue and health conditions such as Hand Arm Vibration Syndrome (HAVS). The condition affects blood vessels, nerves, and muscles in the hands and arms, leading to symptoms including tingling, numbness, and a loss of grip. In severe cases, HAVS can cause finger blanching, also known as "white finger", during cold weather or stress. The condition can become permanent, severely impacting dexterity and hand function. Using a low vibration saw can reduce or eliminate the risk of developing HAVS, in some models of saw the vibration level can be reduced below 3.0m/s².

⚙️ Blade Speed

The speed of a blade is recorded in revolutions per minute (RPM), in simple terms, the faster the blade turns, the greater probability of a smoother and faster cut. A fast turning blade is important especially when cutting difficult materials such as reinforced concrete as this prevents the blade being snagged on the reinforcement.

The RPM of the saw and the blade must align to avoid overheating or blade failure.

⚙️ Maintenance

Regular maintenance is essential for petrol saws to ensure ongoing reliability, given their complex engine systems. Key tasks include checking and cleaning the air filter frequently, especially when operating in dusty environments, as a clogged filter can restrict airflow and reduce performance. The spark plug should also be inspected and replaced periodically to maintain consistent ignition. Monitoring and adjusting the belt tension ensures efficient power transmission to the blade while preventing slippage. Regular cleaning of the cooling system and cylinder fins is critical to prevent overheating.

It is advisable to have your saw serviced annually by a trained technician.

⚙️ Running Cost

The whole life cost running cost of a cut off saw will factor in matters such as fuel consumption, ongoing servicing / maintenance and availability of replacement parts.

Based on a Sthil TS 410 with an approximate fuel consumption rate of 470g/kwh, used at full power for one hour will consume approximately 2 Litres of 50:1 fuel. The cost of this is calculated combining your local source of Petrol with the cost of 2 Stroke Oil.

The cost of ongoing fuelling of a battery saw is greatly reduced by eradicating fuel source and replacing by electric charge. An average charge of a MX Fuel Battery will cost £0.10-£0.20.

It should not be forgotten that Lithium-ion batteries do not maintain their power forever and like many other battery operated devices, lose their efficacy over time. Some key signs of battery fatigue include;

1. Reduced Capacity - Battery loses charges quicker than normal.

2. Longer Charging Time - The battery takes longer to reach full bars on the charger.

3. Overheating - Where the battery produces excessive heat either when charging or in use.

4. Voltage Sag - Where the battery causes the tool to reduce performance under high strain.

With regards to servicing and parts availability, when purchasing an established brand such as Stihl, Husqvarna, Milwaukee, each manufacturer has a comprehensive stock holding of spare parts and accessories to support ongoing maintenance. Whilst the cost of these can be excessive when it comes to replacing larger parts, this typically only occurs when the saw is approaching end of life and therefore a decision should be taken to consider if the tool is beyond economic repair.

Model Comparison

| Model | Image | Power Source | Weight (kg) | Portability | Cut Depth | Noise & Emissions | Vibration Levels (m/s²) | Blade Speed (RPM) | Maintenance | Cost |

|---|---|---|---|---|---|---|---|---|---|---|

| Stihl TS 410 |  |

Petrol (2-Stroke) | 9.6 | High (Compact Design) | 100 mm | High noise, moderate emissions | 3.9 | 5350 | Moderate, air filter system | £750 - £850 |

| Stihl TS 420 |  |

Petrol (2-Stroke) | 9.8 | High | 125 mm | High noise, moderate emissions | 3.9 | 5350 | Moderate, robust design | £800 - £900 |

| Husqvarna K 770 12" |  |

Petrol (2-Stroke) | 10.0 | High (Lightweight) | 100 mm | High noise, moderate emissions | 2.3 | 4700 | Easy maintenance (SmartTension™) | £750 - £850 |

| Husqvarna K 770 14" |  |

Petrol (2-Stroke) | 10.1 | High (Compact Design) | 125 mm | High noise, moderate emissions | 2.3 | 4700 | Easy maintenance (SmartTension™) | £850 - £950 |

| Hilti DSH 600-X |  |

Petrol (2-Stroke) | 6.9 | Very High | 120 mm | High noise, moderate emissions | 3.5 | 5100 | Low, optimised for efficiency | £950 - £1100 |

| Makita EK6100 |  |

Petrol (2-Stroke) | 8.8 | High (Lightweight) | 100 mm | High noise, moderate emissions | 3.0 | 4000 | Moderate, durable parts | £700 - £800 |

| Stihl TS 910 |  |

Petrol (2-Stroke) | 12.9 | Moderate | 145 mm | High noise, moderate emissions | 4.4 | 3970 | Moderate, air filter system | £1500 - £1600 |

| Husqvarna K 1270 16" |  |

Petrol (2-Stroke) | 14.2 | Moderate | 145 mm | High noise, moderate emissions | 4.0 | 8400 | Easy maintenance (SmartTension™) | £1600 - £1800 |

The Stihl TS 410

What they say

"Long-life filter system with cyclone pre-separation makes on site maintenance unnecessary. Extremely low vibration levels (3.9m/s²). High performance engine with stratified charge system. Compact design and optimised balance for excellent cutting and guide characteristics. For use with 300mm cutting wheel. ElastoStart, primer pump and decompression valve. Bayonet filler cap for tool free opening. Can be hand held or used with the FW 20 cart. Supplied with abrasive cutting wheel."

What we say

"The Stihl TS 410 is a dependable and high-quality cut-off saw that consistently delivers excellent performance on-site. We value its balance of power and portability, making it a reliable choice for professionals tackling tough materials like concrete and asphalt. The sleek design and low vibration levels ensure comfort during extended use, while the robust build and efficient two-stroke engine offer durability and impressive cutting power."

Stihl TS420 14"

What they say

"Long-life filter system with cyclone pre-separation makes on site maintenance unnecessary. Extremely low vibration levels (3.9m/s²). High performance engine with stratified charge system. Compact design and optimised balance for excellent cutting and guide characteristics. For use with 350mm cutting wheel. ElastoStart, primer pump and decompression valve. Bayonet filler cap for tool free opening. Can be hand held or used with the FW 20 cart. Supplied with abrasive cutting wheel."

What we say

"The Stihl TS 420 is a high-performance cut-off saw for those looking for a 14" blade. Its powerful engine and versatile cutting capability make it ideal for a wide range of professional applications, from asphalt to metalwork. The well-balanced design, combined with low vibration levels, ensures operator comfort during prolonged use, while its efficient fuel consumption and durable components make it a cost-effective and long-lasting choice."

Stihl TS 910 16"

What they say

"The TS 910i petrol cut-off machine is the most powerful petrol cut-off machine from STIHL, offering the best power-to-weight for a 16” / 400mm cut-off machine. Designed for professionals working in civil engineering, construction and landscaping, it’s capable of taking on demanding tasks such as cutting structural steel, concrete, asphalt or pipes. Comes as standard with a powerful 16” / 400 mm composite resin cutting wheel for steel with very good cutting performance. You can also fit the TS 910i with a D-SB90 diamond cutting wheel for longer and more intensive jobs. Equipped with the innovative, electronically controlled STIHL Injection system, the powerful STIHL 2-MIX engine of this professional cut-off machine results in high torque, 24% power output increase compared to the TS 800, 30% improved fuel efficiency and a significantly easier start procedure (purge and pull). Reduced emissions are further advantages of the STIHL Injection system technology. The TS 910i engine cut-off machine is suitable for cutting depths of up to 145 mm and can be hand-held. The ergonomic handle design and STIHL anti-vibration system means your muscles and joints are protected while you work. The design of the anti-vibration system also helps you to guide the power tool precisely when cutting. You can use the optional STIHL FW 20 cart, which can be used with an adapter, for precise cuts and longer cutting distances – for example in road construction. The positioning of the water connection for binding dust to the cutting wheel also helps you to work effectively, while the long-life air filter system extends intervals between cleaning for longer uninterrupted working time. The TS 910i drive can easily be re-tensioned using the semi-automatic belt tensioning function, which extends the life of the belt and bearing."

What we say

"The Stihl TS 910 i is a robust and powerful cut-off saw, designed for professional use in demanding applications, where a 400mm blade is required. However, its relatively large size and engine power might be overkill for lighter or less frequent tasks. While it provides excellent durability and reliability, its fuel consumption and maintenance requirements are typical of high-performance petrol saws, which might deter users looking for a more cost-efficient solution. Overall, the TS 910 i is a strong choice for heavy-duty work but may not be the most economical option for all users."

Stihl TSA 300 12" Battery

What they say

"The TSA 300 is a 12” (300 mm) battery-powered cut-off machine in the STIHL AP System. It’s exceptionally easy to handle thanks to its compact and well-balanced design and is designed for professionals working in construction, hardscaping and pipework – making it an ideal choice for processing materials such as bricks, paving stones, natural stone, concrete, reinforced concrete and rebar. Fitted as standard with a K-ME abrasive cutting wheel, the TSA 300 has cutting performance that is comparable to the TS 410 petrol cut-off machine because of the narrow cutting kerf. This is achieved thanks to the lack of engine vibrations. It increases precision when making cuts, meaning you can achieve accurate results at all times and allows for a maximum cutting depth of 4.3" (110 mm). You can also fit the TSA 300 with a D-SB90 diamond cutting wheel. As the TSA 300 is battery-powered, it has low noise emissions during cutting. It is fitted with a powerful EC motor which operates almost wear-free, is quiet and has smooth running and low vibrations – it also ensures the tool operates at optimum performance throughout the entire battery charge. Fitted with a STIHL magnetic filter which passes cooling air through several magnets, protecting the internal components from metal dust and particles. These magnets can be easily removed for fast cleaning, ensuring a long-service life. This tool is fitted with a fast-stop brake that recuperates energy into the battery. After releasing the trigger, the wheel is stationary in less than 4 seconds which loads the energy from the TSA 300 back into the battery, which increases your working time. As the TSA 300 is battery-powered and has zero emissions, it can also be used indoors. It also has a LED display on the handle which provides you with information such as operating speed and an overheating warning. The TSA 300 must be used with the AP 500 S battery for maximum performance. If you use an AP 200 S or AP 300 S, there will be a reduction in performance. On a full charge with the AP 500 S, the TSA 300 has a working time of 20 minutes."

What we say

"The Stihl TSA 300 is a lightweight and well-designed battery-powered cut-off saw that offers excellent maneuverability and ease of use. Its compact size and low vibration levels make it comfortable for extended use, particularly in environments where emissions and noise are concerns. However, the high initial cost of the tool, combined with the expense of additional AP-series batteries and chargers, makes it a significant investment compared to petrol-powered alternatives. The limited runtime of the battery system can also be a drawback for users who require extended operation times. While the TSA 300 shines in design and portability, its high cost and battery dependency may leave some users disappointed."

Husqvarna K770 12"

What they say

"The Husqvarna K 770 14" is a powerful all-around power cutter with features that make it one of the best power cutters on the market. Equipped with a semi-automatic SmartTension™ system allows for optimal power transmission, minimum wear and maximum belt life. The lightweight, outstanding power-to-weight ratio, reliable start and exceptionally low vibrations mean less strain and maximised productivity. Suitable for road work and easy to cut in a straight or curved track or close to the sidewalk when used with a KV7 trolley."

What we say

"The Husqvarna K770 12" is an outstanding cut-off saw that sets a high standard for power and performance in its class. Its robust 3.7 kW engine delivers exceptional cutting strength, making it ideal for tackling tough materials like concrete, asphalt, and stone with ease. The saw's power-to-weight ratio is particularly impressive, ensuring it remains manageable without compromising cutting performance. Additionally, features like the semi-automatic SmartTension system and long service intervals add to its reliability. For professionals seeking a saw that combines superior power with usability, the K770 12" is a top-tier choice."

Husqvarna K770 14"

What they say

"The Husqvarna K 770 14" is a powerful all-around power cutter with features that make it one of the best power cutters on the market. Equipped with a semi-automatic SmartTension™ system allows for optimal power transmission, minimum wear and maximum belt life. The lightweight, outstanding power-to-weight ratio, reliable start and exceptionally low vibrations mean less strain and maximised productivity. Suitable for road work and easy to cut in a straight or curved track or close to the sidewalk when used with a KV7 trolley."

What we say

"The Husqvarna K770 14" builds on the strengths of its 12" counterpart, offering the same exceptional power and reliability but with the added benefit of a larger cutting capacity. Like the 12" model, the 14" version features a powerful 3.7 kW engine, delivering impressive cutting performance for demanding materials such as concrete and asphalt. For users who need the enhanced versatility of a deeper cutting depth without compromising on power or usability, the K770 14" is a superb choice."

Husqvarna K1270 16"

What they say

"Some jobs require exceptional power. The K 1270 is a real powerhouse with an impressive 5,8 kW output, turning your heaviest cutting jobs into a fast and effective operation. Suitable for road works when used with the corresponding KV 9/12 trolley. The trolley also means you can fully concentrate on the cutting job."

What we say

"The Husqvarna K1270 cut-off saw is a powerhouse designed for the most demanding cutting tasks, delivering exceptional performance with its 5.8 kW engine. This level of power makes it highly effective for heavy-duty applications like cutting reinforced concrete, stone, and metal, particularly at depth. Despite its strength, the K1270's ergonomic design and vibration-dampening features help reduce operator fatigue during extended use. However, its significant size and weight, along with higher fuel consumption compared to smaller models like the K770, may make it less practical for everyday or lighter tasks. For those requiring unmatched power and durability for challenging projects, the K1270 is a remarkable tool."

Husqvarna K1 PACE 12" Battery

What they say

"K 1 PACE high power battery cutter has the power and performance you expect from equivalent petrol-powered cutters. Equipped with X-Halt™ brake function for operational safety. Ergonomic and user-friendly with low vibrations, optimally balanced machine and zero CO₂ emissions during use. With built-in connectivity so you can easily monitor machine location, runtime, service intervals and receive wireless updates through FOTA (firmware over the air). Powered by Husqvarna PACE battery system with high power and fast charging for impressive productivity and a well-suited match with our specially designed battery blade range for maximised cutting depth and optimised performance. Suitable for concrete pipes, concrete garden plates, cinder blocks etc."

What we say

"The Husqvarna K1 PACE battery cut-off saw offers a sleek and lightweight design that is both modern and highly ergonomic, making it comfortable to handle and ideal for precision work. Its reduced vibrations and emission-free operation make it an attractive choice for environmentally-conscious users or those working in indoor and noise-sensitive environments. However, its high initial cost and the expense of additional batteries can be a significant drawback, especially for contractors needing extended runtime on large projects. While the saw performs well within the limits of its battery power, it will struggle to match the endurance and cutting capacity of petrol-powered models. For light to moderate use, the K1 PACE is a solid option, but its cost and reliance on battery technology may not justify the investment for all users."

Milwaukee MXF COS350G2 14"

What they say

"Battery powered, it can be used indoors due to zero fume emissions Anti-kickback system prevents users from being injured in case of a kickback RAPIDSTOP™/ blade brake: blade stops within < 3 sec Petrol equivalent performance with a maximum no load speed of 5370 rpm and a full 125 mm depth of cut Faster cuts, start to finish: 3 second push button start up eliminates the need to mix petrol and oil, and avoids petrol engine maintenance 350 mm battery powered cut-off saw to deliver the power to cut reinforced concrete Supplied with HUDD 350 mm diamond blade (4932471985) & contractor bag For precise long cuts to be used with the MX FUEL™ cut-off saw cart On-board water line for wet cutting which is compatible with the M18™ SWITCH TANK™ interchangeable sprayer and water supply system Building on the strengths of the FUEL™ technology, MX FUEL™ system reaches new levels of cordless performance. Focused on petrol, corded and pneumatic performance, these tools deliver without the hazards associated with emissions, noise, vibration, tripping hazards and the frustrations of complex maintenance ONE-KEY™ tool tracking & security offers a free of charge cloud-based tracking network and inventory management platform for your tools. ONE-KEY™ also features a remote locking function"

What we say

"The Milwaukee MXF COS350G2 14" cut-off saw is a game changer tool that redefines versatility and efficiency in professional cutting equipment. Powered by the MX FUEL™ system, this saw features multi-use batteries that seamlessly integrate across the Milwaukee MX FUEL™ range, including the compactor plate and other heavy-duty tools. This compatibility not only streamlines operations but also maximises the value of each battery investment, offering unmatched convenience for contractors managing multiple tasks. With a powerful motor delivering petrol-equivalent performance, zero emissions, and rapid push-button start, the MXF COS350G2 is perfect for both indoor and outdoor use. The saw’s ergonomic design and anti-kickback system enhance safety and user comfort, while its impressive cutting depth and precision ensure it meets the demands of challenging materials like reinforced concrete and asphalt"

Hilti DSH600-X

What they say

"Compact top-handle petrol saw (63cc) with blade brake, for cutting up to 120 mm with 300 mm blades in concrete, masonry and metal"

What we say

"The Hilti DSH600-X cut-off saw is a solid, mid-range option for professionals seeking reliability without high-end features. Its compact design and manageable weight make it easy to handle on smaller tasks, while the engine provides adequate power for cutting through common materials like concrete and masonry. The saw’s build quality is durable, and it offers reasonable cutting performance for its size, though it falls short of the power and versatility seen in other models within the same class. For those who prioritise simplicity and dependability over cutting-edge features, this saw gets the job done without standing out as exceptional."

Makita EK6100

What they say

"A light but powerful cutter with a two-stroke engine for applications such as construction and rescue operations. The max. cutting depth is 110 mm"

What we say

"The Makita EK6100 cut-off saw leaves much to be desired for professional users seeking reliability and performance. While its compact size and lightweight design are convenient, the saw struggles to deliver consistent power when cutting through tougher materials like reinforced concrete or dense masonry. The engine, though serviceable, lacks the robustness and efficiency of competitors in the same category, often leading to slower cutting speeds and more frequent maintenance. For users who demand consistent performance and rugged durability, the EK6100 falls short, making it a less appealing choice compared to more capable options in the market."

Summary

The world of disc cutters has never been more diverse or innovative, offering solutions for every professional need, from the robust and reliable petrol-powered Stihl and Husqvarna models to the cutting-edge battery technology of Milwaukee and Husqvarna’s K1 PACE. Each manufacturer brings unique strengths, with Stihl’s long-standing reputation for durability, Husqvarna’s smart engineering, Milwaukee’s groundbreaking battery compatibility, and Hilti and Makita providing alternatives for niche applications. The choice ultimately depends on the specific requirements of your projects, whether prioritising power, portability, or sustainability. As the industry moves towards more environmentally friendly and low-maintenance options, the landscape of disc cutters continues to evolve, ensuring there is a tool perfectly suited to every challenge.

Frequently Asked Questions

Q: What is the difference between a Cut Off Saw, a Disc Cutter and a Power Cutter?

A: The simple answer is nothing! These are all different terms used to describe a saw which drives a diamond or abrasive disc in cutting various materials.

Q: What materials can a Stihl saw cut?

A : It can cut most materials, depending on the blade fitted to the saw. Most common products cut by this type of saw include concrete, asphalt, hard materials, metal, steel, reinforced concrete and much more.

Q: Where can I buy any of these saws?

A: Red Stag Materials specialise in equipment for cutting, compaction, asphalt surfacing and power generation. Whilst we have a large selection of equipment listed on our website, we regularly supply a wide range of products. Contact us with your specific requirements and we will be able to assist. sales@redstagmaterials.com

Q: How long does it take to charge a Stihl saw battery?

A: A Stihl AP 500 S battery will take approximately 45 minutes to achieve 80% charge and 60minutes to reach 100%.

Q: What other products do I need with a Stihl saw?

A: It's essential to use a good quality Two Stroke Engine Oil.